1. What Are Enerfit Applications

Enerfit is a retrofit for single-zone rooftop commercial air conditioning units that will cut the annual air conditioning electrical consumption in half or better.

Enerfit will work on package, split-systems or heat pumps as long as they are not VAV (Variable Air Volume) or VVT (Variable Volume & Temperature).

2. How Does It Save So Much Energy?

Enerfit controls the indoor (evaporator) fan speed in response to the operating mode of the unit.

Compared to other solutions which place a blind guess at the actual effects of slowing down the fan, Enerfit deploys a set of advanced sensor and powerful real-time controls in cooling mode to drive verifiably safe (and much more dramatic) energy savings.

Compared to other solutions which place a blind guess at the actual effects of slowing down the fan, Enerfit deploys a set of advanced sensor and powerful real-time controls in cooling mode to drive verifiably safe (and much more dramatic) energy savings.

Enerfit limits relative humidity by up to 15% in cooling mode. It also reduces drafts in the winter and shoulder months. The overall result is dramatically improved occupant comfort and a decrease (or in many cases total elimination) of comfort complaints.

For a deeper dive into the mechanics and science involved check out our page on The Engineering.

3. How Does The Sales Process Work?

Every Enerfit is quoted and built specifically for the unit on which it's applied.

There is an immense amount of engineering and programming behind each kit, but the information required from the customer is straightforward and minimal.

Click here for a PDF with unit scounting procedures and info submittal.

Click here for a PDF with unit scounting procedures and info submittal.

4. How Do You Calculate Payback?

First things first: HVAC isn't lighting. There are a lot more variables and it requires deep historical climate data to properly model and project Enerfit’s advanced retrofit savings.

We’ve built a next generation model based on equal parts engineering analysis and historical savings data sampled from Enerfit sites across the United States. All savings are also backed by a detailed psychrometric (humidity vs. temperature) analysis as well.

We’ve built a next generation model based on equal parts engineering analysis and historical savings data sampled from Enerfit sites across the United States. All savings are also backed by a detailed psychrometric (humidity vs. temperature) analysis as well.

Our model runs on a large Excel engine that uses hourly weather bin data.

The analysis takes into account DCV retrofits, climate conditions, fan motor loading, demand charges and work schedules (and that's just the beginning).

The analysis takes into account DCV retrofits, climate conditions, fan motor loading, demand charges and work schedules (and that's just the beginning).

5. But How Do You Prove It?

In real-time, live on the controller.

Onboard M&V (Measurement & Verification) is hard coded into every new Enerfit controller. Using kWh information pulled from the sensors on the VFD (Variable Frequency Drive), the unit even self-calibrates periodically to ensure precision.

Customers can view the cumulative and live savings statistics though enteliWeb, CopperTree, a wall-mounted touchscreen or over their existing BAS (Building Automation System).

Customers can view the cumulative and live savings statistics though enteliWeb, CopperTree, a wall-mounted touchscreen or over their existing BAS (Building Automation System).

6. What's the End Result?

Using a typical 20 Ton RTU as an example…

kWh Savings

After years of testing multiple climates, unit sizes and configurations, Enerfit typically saves at least 50% of the annual electrical consumption of the unit.

In cases where the units are very oversized - often because of cautious engineering or where lighting retrofits have reduced the original heat load - we have seen savings well beyond the 50% range.

In cases where the units are very oversized - often because of cautious engineering or where lighting retrofits have reduced the original heat load - we have seen savings well beyond the 50% range.

Simple Payback

Using a typical 20 ton RTU with typical run hours (4800/yr) and typical utility rates, Enerfit will pay back in less than two years.

If the run hours are higher (24/7/365), the payback would be closer to one year.

Adding DCV (Demand Control Ventilation) will also improve electrical savings further and improve gas savings in cold months.

Economizer control is an easily added onboard option that meets California Title 24 for dry bulb comparison economizer or enthalpy comparison economizer control.

If the run hours are higher (24/7/365), the payback would be closer to one year.

Adding DCV (Demand Control Ventilation) will also improve electrical savings further and improve gas savings in cold months.

Economizer control is an easily added onboard option that meets California Title 24 for dry bulb comparison economizer or enthalpy comparison economizer control.

Note: These simple payback numbers do not take into account any utility incentives (which are very common in the Northeastern and Western US) or any of the other "soft savings" provided by Enerfit.

Soft savings include better alarming, shorter maintenance time required, extended unit life, and decreased space humidity.

Soft savings include better alarming, shorter maintenance time required, extended unit life, and decreased space humidity.

7. But What About The Little Guys?

Enerfit now also produces a specialty product for smaller (2-7 ton) units that uses the same processor as the standard Enerfit but reduces unnecessary I/O.

Code-named "Stumpy", the result is a smaller form factor that compromises nothing on performance but weighs in at a lower cost for small units.

8. ROI: The Untold Story

The return on any HVAC investment is only as good as the people who service and maintain it.

Enerfit adds a whole new set of proactive unit alarms (in addition to the basic factory alarms) and real-time data streams on the controller.

These data streams are also available to larger building network and analytics systems for centralized monitoring.

These data streams are also available to larger building network and analytics systems for centralized monitoring.

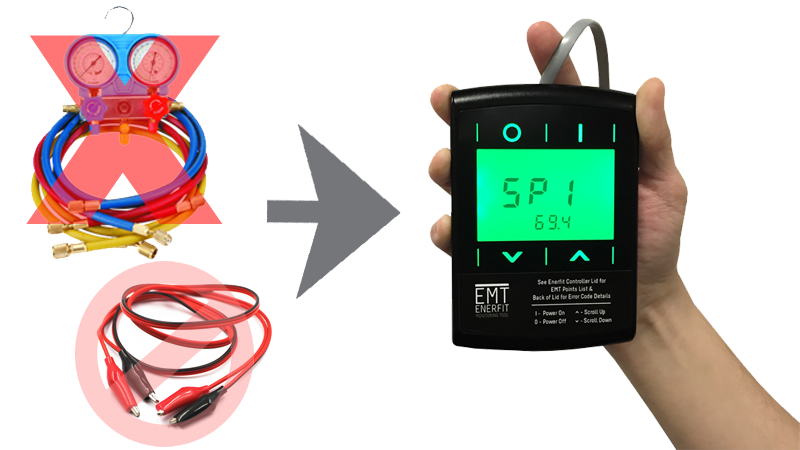

Service technicians save hours of tedious labor using the detailed data on the attached EMT (Enerfit Monitoring Tool) and their work can be easily checked by an onsite facilities manager or remote BAS / analytics software.

Read more about those solutions at The Data.

Read more about those solutions at The Data.